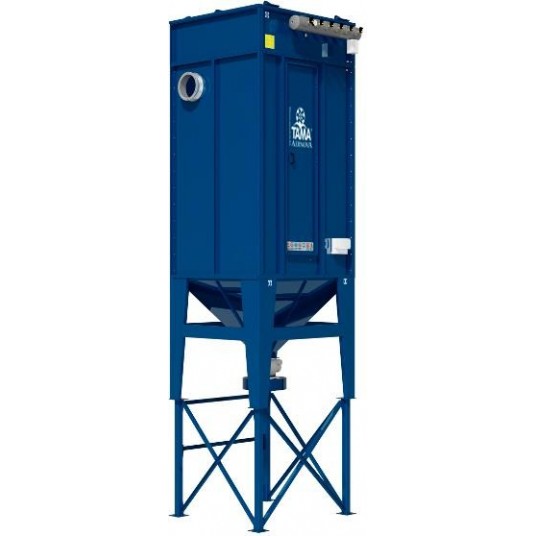

Baghouse filter Pulco Air

The baghouse filter Pulco Air is a dry filtration system used to purify the air from suspended solid particles.

Advantages

Thanks to the installation of the baghouse dust collector Pulco Air it is possible to treat a wide range of pollutants, even in the presence of high temperatures or humidity, by ensuring the quality of the air in the production environment and protection for workers. Filter elements cleaning is managed by pressure drop reading, favouring a lower compressed air consumption and an increased life for bags.

How it works

The dusty air is conveyed to the filter bags from the outside to the inside, depositing the impurities on the external part of the filter elements and in the collecting hopper. A compressed air jet, stored in a special tank, is injected cyclically in the bags, creating a wave of shaking able to detach and topple the particles deposited on the external part of the bags.

Standard equipment for all the configurations

- Filtration chamber

- Hopper with support legs

- Cleaning pneumatic system of the bags controlled by differential pressure switch

Optional equipment for all the configurations

- Tank cover

- Control panel cover

- Electrical panel

- Pressure regulator

- Level probe

The baghouse filter Pulco Air conforms easily to specific needs: it is combinable in its main parts directly by the costumer according to specific needs and type of use. The different configurations in the catalogue come from the mix of the following variants:

- Type of inlet of dirty air (presence or not of pre-filtering chamber for the collection of the biggest dust, it has the task of protecting the bags from excessive load of pollutant);

- Type of dust discharge (collection bin; rotary valve for continuous discharge; combined action of screw and rotary valve);

- Means of access to the maintenance door and its placement.

- Possibility of use in ATEX area (presence or not of components suitable for use in the presence of potentially explosive mixtures).

-

Baghouse Filter Pulco Air NSB

Configuration with dirty air inlet directly into the hopper, frontal extraction system of the filtering elements, dust discharge in a special bin placed under the hopper.

Optional equipment for the configuration

- Staircase and walkway to access the maintenance door

- Fan + soundproof box to lower the noise produce by the engine (on the top or on the ground)

- Deflector in hopper

-

Baghouse Filter Pulco Air CSB

Configuration with dirty air inlet consisting of a pre-filtration chamber, frontal extraction system of the filtering elements, dust discharge in a special bin located under the hopper.

Optional equipment for the configuration

- Staircase and walkway to access the maintenance door

- Fan + soundproof box to lower the noise produce by the engine (on the top or on the ground)

-

Baghouse Filter Pulco Air CSV

Configuration with dirty air inlet consisting of a pre-filtration chamber, frontal extraction system of the filtering elements, dust discharge through the action of the rotary valve.

Optional equipment for the configuration

- Staircase and walkway to access the maintenance door

- Fan + soundproof box to lower the noise produce by the engine (on the top or on the ground)

-

Baghouse Filter Pulco Air CSC

Configuration with dirty air inlet consisting of a pre-filtration chamber, frontal extraction system of the filtering elements, dust discharge through the combined action of rotary valve and screw conveyor.

Optional equipment for the configuration

- Staircase and walkway to access the maintenance door

- Fan + soundproof box to lower the noise produce by the engine (on the top or on the ground)

-

Baghouse Filter Pulco Air NTC

Configuration with dirty air inlet directly into the hopper, extraction system from the top of the filtering elements, dust discharge through the combined action of a rotary valve and screw conveyor.

Optional equipment for the configuration

- Deflector in hopper

- Fan + soundproof box to lower the noise produce by the engine (on the top or on the ground)

- Maintenance door

-

Baghouse Filter Pulco Air CTC

Configuration with dirty air inlet consisting of a pre-filtration chamber, extraction system from the top of the filtering elements, dust discharge through the combined action of rotary valve and cochlea.

Optional equipment for the configuration

- Fan + soundproof box to lower the noise produce by the engine (on the top or on the ground)

- Maintenance door

-

Baghouse Filter Pulco Air NSVA

Configuration with dirty air entering directly into the hopper, frontal extraction system of the filtering elements, dust discharge through the action of the rotary valve, components suitable for the ATEX zone.

Optional equipment for the configuration

- Staircase and walkway to access the maintenance door

- Deflector in hopper

- Fire prevention system with tubes, sprayer nozzles and temperature probe

- Fan + soundproof box to lower the noise produce by the engine (on the top or on the ground)

-

Baghouse Filter Pulco Air CSVA

Configuration with dirty air inlet consisting of a pre-filtration chamber, frontal extraction system of the filtering elements, dust discharge through the action of the rotary valve, components suitable for the ATEX zone.

Optional equipment for the configuration

- Staircase and walkway to access the maintenance door

- Fire prevention system with tubes, sprayer nozzles and pt100 probe

- Fan + soundproof box to lower the noise produce by the engine (on the top or on the ground)

-

Baghouse Filter Pulco Air CSCA

Configuration with dirty air inlet consisting of a pre-filtration chamber, frontal extraction of the filtering elements, dust discharge through the combined action of a rotary valve and a cochlea, components suitable for the ATEX zone.

Optional equipment of the configuration

- Staircase and walkway to access the maintenance door

- Fire prevention system with tubes, sprayer nozzles and pt100 probe

- Fan + soundproof box to lower the noise produce by the engine (on the top or on the ground)

-

Baghouse Filter Pulco Air NTVA

Configuration with dirty air entering directly into the hopper, extraction system from the top of the filtering elements, dust discharge through the action of the star valve, components suitable for the ATEX zone.

Optional equipment of the configuration

- Deflector in hopper

- Fire prevention system with tubes, sprayer nozzles and temperature probe

- Fan + soundproof box to lower the noise produce by the engine (on the ground)

-

Baghouse Filter Pulco Air CTVA

Configuration with dirty air inlet consisting of a pre-filtration chamber, extraction system from the top of the filtering elements, dust discharge through the action of the rotary valve, components suitable for the ATEX zone.

Optional equipment of the configuration

- Fire prevention system with tubes, sprayer nozzles and pt100 probe

- Fan + soundproof box to lower the noise produce by the engine (on the ground)

-

Baghouse Filter Pulco Air CTCA

Configuration with dirty air inlet consisting of a pre-filtration chamber, extraction system from the top of the filtering elements, dust discharge through the combined action of a rotary valve and cochlea, components suitable for the ATEX zone.

Optional equipment of the configuration

- Fire prevention system with tubes, sprayer nozzles and pt100 probe

- Fan + soundproof box to lower the noise produce by the engine (on the ground)

-

Baghouse Filter Pulco Air NSVX

Configuration with dirty air entering directly into the hopper, frontal extraction system of the filtering elements, dust discharge through the action of the rotary valve, components suitable for the ATEX zone with explosion-proof panels installed on the roof.

Optional equipment of the configuration

- Staircase and walkway to access the maintenance door

- Deflector in hopper

- Fire prevention system with tubes, sprayer nozzles and temperature probe

- Fan + soundproof box to lower the noise produce by the engine (on the top or on the ground)