Combustion processes aimed at the production of thermal energy, but also electricity in thermoelectric and cogeneration plants, release important quantities of particulate invisible to the human eye. We are talking about PM (particulate matter), a set of substances present in the air that is particularly dangerous because, being very thin, penetrates into the human organism reaching the lungs. According to the exposure to which a person is undergone, various health problems can arise, including cardiovascular and pulmonary diseases. Recent studies quantify that in Italy there are over thirty thousand deaths a year due to fine particles (stateofglobalair.org). The only way to minimize combustion harmful effects during industrial processes is to equip plants with fumes filtration systems installed after the burner.

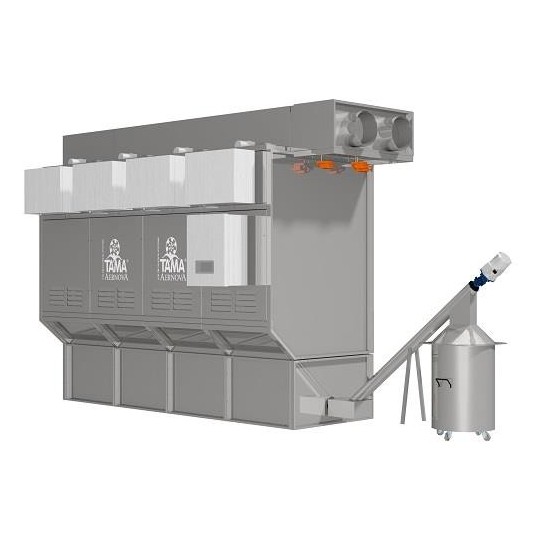

TAMA AERNOVA provides specific solutions for each type of combustion process, allowing a coexistence between production needs and health protection. Our offer of products designed and developed to meet the needs of this sector includes baghouse filter, cyclones and electrostatic filters optimized for working also with high temperatures, and also cylindrical baghouse filter suitable to tolerate high pressure during suction of dusts coming from ashes transport.

- Baghouse Filter for High Temperatures

- ESP Electrostatic Collector

- Cyclone Separators & Collectors

- Lime dosing system

Baghouse Filter for High Temperatures

ESP Electrostatic Collector

Cyclone Separators & Collectors

Lime dosing system