Industrial air: filtration 4.0 for the Waste&Recycling sector

Although appearances may fool the inexperienced, filters for purifying air from suspended solid particles within an industrial or manufacturing setting are not all the same. We are not just talking about the physical dimensions and macroscopic appearance of the filtration equipment. The most substantial differences, which determine the uniqueness and appropriateness of the solution for the designated purpose, are more likely to be defined by design interventions related to variables of fundamental importance, such as: the nature of the pollutants; the velocity, temperature, and humidity of the airflow; the calculation of the pressure drop; the collection and storage options for solid residuals, which may be subject to cross-contamination or generate potentially explosive atmospheres; the operational compatibility with the various pieces of machinery and the production objectives.

In fact, depending on the specific needs of process dust control and management, it is essential to make choices that, by intervening upstream of filter construction, can guarantee its efficient operation, in compliance with performance requirements, industry standards and permitted emission regulations. Each situation is essentially unique; the relationship with the Customer is thus fundamental, as it is a prerequisite to the possibility of offering a performing and functional product that meets expectations.

REDUCE, REUSE, RECYCLE: FILTERS AND CUSTOM SOLUTIONS FOR A SUSTAINABLE INDUSTRY

Since 1983, the year of its foundation, TAMA AERNOVA has been committed to the development of technologies that, through the Best Available Techniques (BAT), aspire to contain the environmental impact of manufacturing and industrial sectors. Thanks to the skills and experience of its engineers and technicians, the company has been able to implement its expertise, proving to be a reliable interlocutor for all those realities ready to transpose and take on board the dictates of the industry of the future - as attentive to profit as to people and to the planet. Among these, the industries involved in waste processing and treatment are prominent

The culture of the non-proliferation of waste inspired by the 3Rs of sustainability – Reduce, Reuse, Recycle – is now a broad strategy for business models based on circular economy metrics, where non-virgin raw material plays a crucial role in generating material and symbolic value. Design solutions, operational support and easy logistics are among the main demands of customers constrained by industry requirements and regulations. Knowing how to understand, acknowledging and anticipating possible issues can really make a difference.

SECONDARY ALUMINUM FOR THE FOOD INDUSTRY: THE PULCO AIR CASE

Challenging timelines, in-depth specializations, international logistics for exceptional dimensions, customers operating on a global scale with specific regulatory frameworks in place are just some of the issues that a company like TAMA AERNOVA must address and sort out daily.

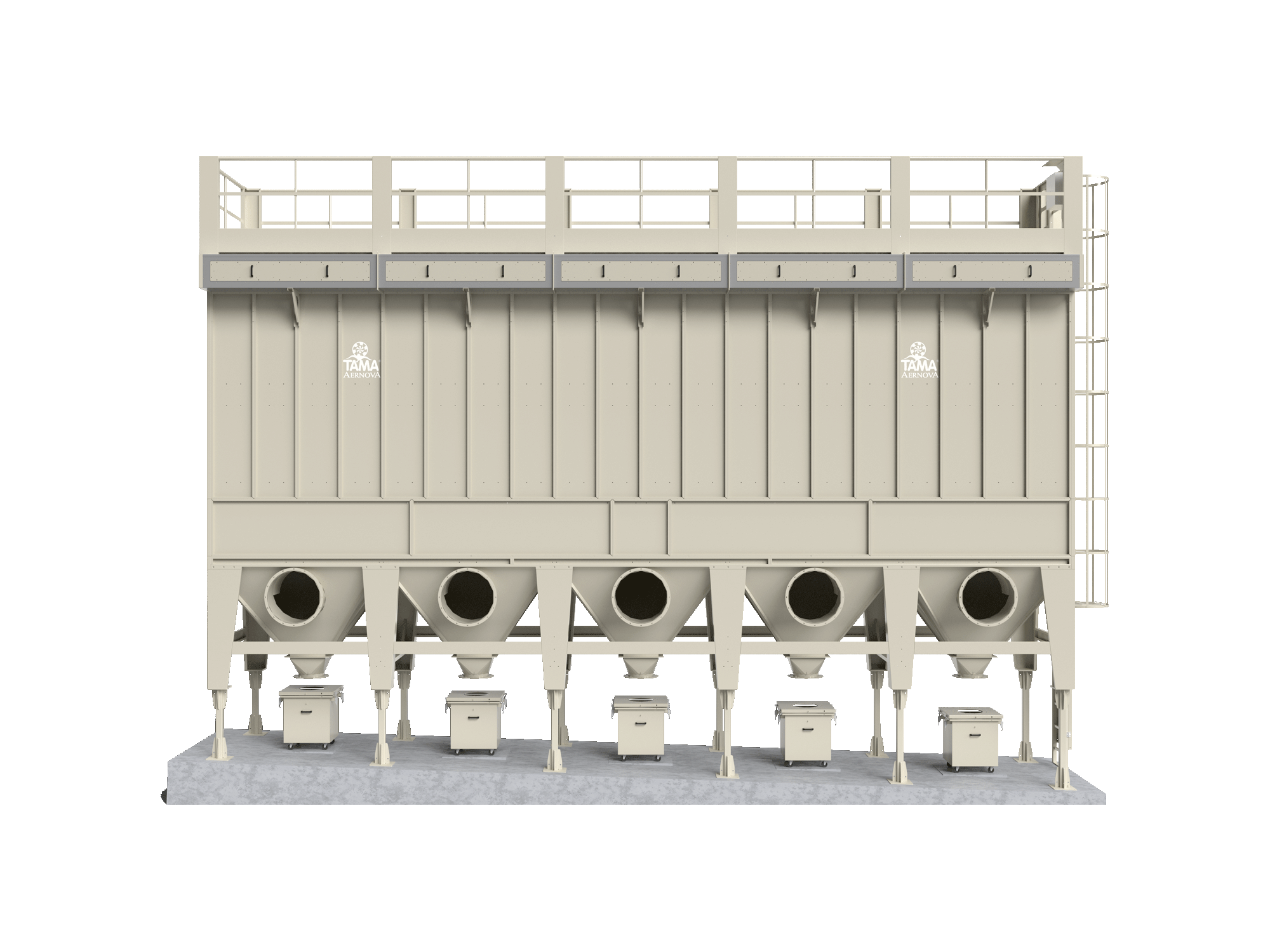

As was the case with one of the most recent and successfully filled orders: a filtration plant for a Canadian manufacturer of recycled aluminium containers and packaging for the food market.

The U.S. General Contractor's request regarding the need for an approved and certified filtration system capable of handling serial production without generating interruptions was the prerequisite for the case in point.

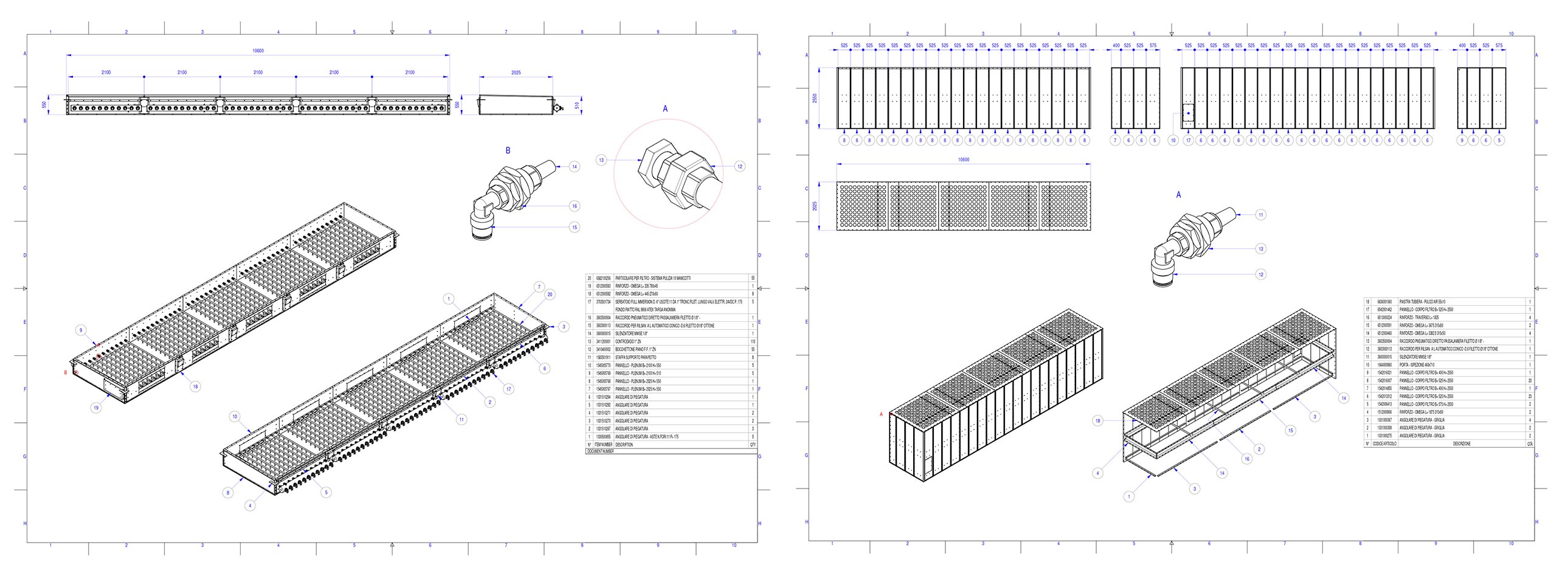

The Pulco Air baghouse filter - identified as best for purpose - was configured based on the production volumes and features of the target site. After being sized to fit the parameters involved, establishing the number of bags (550) needed to handle the incoming air flow on the basis of the pollutant, the filter unit was equipped with the elements necessary for ATEX certification, making it suitable for operation in the presence of potentially explosive atmospheres.

In addition to giving due consideration to the nature of the particulates and volatile compounds to be handled as part of the filtration processes, TAMA AERNOVA's signature design includes several feasibility analyses regarding the positioning of the system in the customer's plant and the logistical complexity involved in transporting large machinery - variables that if not considered already in the conceptual stages, can significantly affect the timing and overall cost of the purchase operation.

A proper study of the destination site, for example, allows filtering machinery to be located in spaces not originally designed for the purpose, and allows for a profitable interaction between the plant and the production line. This prevents stoppages or delays being generated. By the same token, the judicious, conscientious management of handling, transportation and delivery of the finished product relieves the customer of problems and complications related to bureaucracy and customs formalities.

TAMA AERNOVA’s filters and systems are manufactured in the two Italian company’s facilities, where they are designed, built and assembled and their functionality tested. Each filter component is individually verified and labelled for faster identification, empowering end users to be autonomous in setting up and handling the filter. The creation of a disassembly and packaging system specifically designed to reduce overall dimensions and transportation costs, on the other hand, allows for more agile handling that is less costly in terms of economics and energy and produces significant savings in time and money. It is thanks to expedients related to logistics and product handling that TAMA AERNOVA substantiates and motivates its competitive positioning internationally; in addition to 40 years of experience and activity in the field of industrial air filtration.

Commenti